Guide to Propylene Glycol for Beer Brewing

Temperature control is critical for both making and enjoying beer. Propylene glycol is an effective coolant that can be used at multiple stages during the brewing process and to help keep beer cold when it is served on tap.

Propylene glycol comes from petroleum and is a viscous, colorless, odorless substance with a slightly sweet taste. Here’s what you need to know to use it safely and effectively in brewing.

Only Use Food-Grade

Propylene Glycol

Propylene glycol is available in both industrial and food grades. You must use the food-grade version for brewing. The most controlled grade is called propylene glycol USP (United States Pharmacopeia). It is manufactured and distributed according to high industry standards.

The cheaper, industrial grades of glycol may not be suitable for recirculation systems and could damage brewing equipment. Ethylene glycol is toxic and should not be used in any food product or production.

Resources:

55-gallon drum of food-grade propylene glycol

330-gallon tote of food-grade propylene glycol

With orders from Keller-Heartt, you get free shipping!

When to Use Propylene Glycol in Brewing

There are different steps in the brewing process where

propylene glycol can be used, including:

- Wort production

- Fermentation

- Packaging

- Pouring through long-draw lines

Wort Production

Wort is susceptible to oxidative damage if it cools too slowly. Slow cooling allows dimethyl sulfide (DMS) to build up, which can taint the brew. Rapid cooling of the wort to about 77 degrees Fahrenheit minimizes oxidation. Rapid cooling also gives proteins in the wort a thermal shock and stops their production.

Pass the wort through a single- or double-stage plate heat exchanger for rapid cooling. Use a glycol water mix on the water circuit. Use a double-walled food-grade heat exchanger to prevent contamination between the wort and the cooling fluid.

Fermentation

Yeast consumes sugars and releases heat. This can lead to overheating. Again, a chiller system using a glycol water mix can prevent a bad brew.

Packaging

Breweries can use the glycol they already have on hand for chilling their beer for packaging if their system is large enough. A chilled glycol fan coil can be added to a chiller. This can then be circulated through a cold storage room. This may lower installation costs versus other refrigerant options and let you utilize the glycol you already have in supply.

Pouring Through Long-Draw Lines

A cold one on tap is one of life’s simple pleasures. A glycol chiller can help a brewery or beer hall ensure each pour is ice cold. Insulating a long-draw beer line alongside a glycol water mix line takes minimal design and installation time.

Using the Right Amount of Glycol

To save money on supplies, you want to get the right glycol-to-water ratio for each of your cooling applications. The more glycol in your mix, the faster it will cool, and the lower its freezing temperature will be.

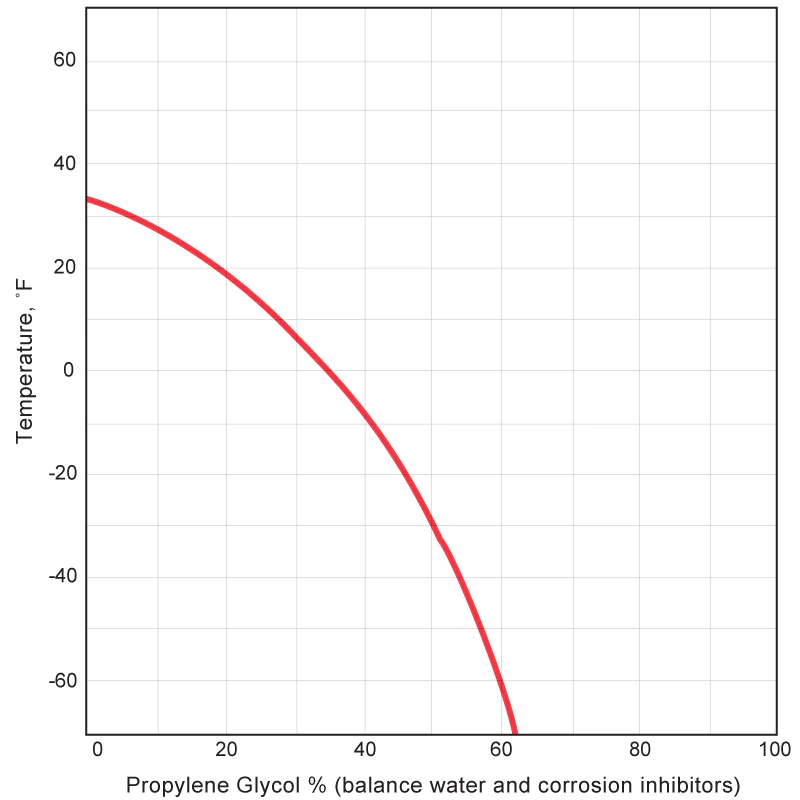

A common standard for many breweries is to use a mix that is 35%-40% glycol. This ratio cools fast enough for most brewing and serving needs. One common mistake is assuming a chiller system at 27 degrees Fahrenheit only needs the freezing point to be below that. But the temperature of the refrigerant will be 10-15 degrees Fahrenheit below the glycol solution temperature.

Example: chiller set point = 27 degrees Fahrenheit; glycol freeze level = 12-17 degrees Fahrenheit.

A good rule of thumb is to have a freezing level of your glycol/water solution 20-25 °F. below your chiller system. This will prevent lines from fully freezing and bursting. This is critical in closed-loop systems exposed to freezing temperatures. Consult the manufacturer of your glycol for specific recommendations around the “burst point” rating.

Freezing Points of Aqueous Solutions of Propylene Glycol

Since each chiller system is built differently, you must consult your manufacturer on the proper glycol dilution percentage. However, a general rule of thumb suggests less glycol is best when you’re on the fence. Since propylene glycol is highly viscous, too heavy of a solution may put extra stress on your pumps. Look at your manufacturer’s indicated burst point on your equipment, too. That is the temperature when equipment becomes vulnerable to swelling in pipes or gaskets. If those fail, your machine will be damaged and your beer contaminated.

Determining How Much Glycol You Need

First, calculate your total system volume. Next, add the estimated volume of your total system piping, plus your tank jackets, and the reservoir size on your chiller system. You can get your chiller system tank capacity from the equipment manufacturer, and your plumber or tank manufacturer can help with piping and jacket volume estimates.

Specifically for wort production, here are the things that’ll impact

the amount of glycol you need in a chiller:

- Volume of the wort to be cooled (this will be in BBL and 1 BBL = 42 gallons)

- Knockout time goal (the cooling time for the process)

- Initial wort temperature

- Final wort temperature

Tips for Smart Setup and Maintenance to Save Money

Keeping on top of your system will save you from having to make

repairs or replacements. These tips will help:

- Keep your setup as simple as possible. Limit places where propylene glycol can build up, like joints and connectors.

- Place coolant systems as close to your tanks as you can to reduce installation costs and cut down on transit lines.

- Use a refractometer to measure the amount of glycol in your mix. Even though propylene glycol does not contain sugars, it affects the refractive index. You can always have the system manufacturer test the freeze point/concentration by sending them solution samples.

- Replace your glycol when needed. Propylene glycol is good for two years from when it is manufactured. Keeping it out of direct sunlight in sealed drums or totes is best.