Choosing the right engine oil is one of the most meaningful decisions an aircraft owner or operator can make.

Unlike automotive engines, piston aircraft engines operate under significantly higher temperatures, greater loads, and far longer intervals between use.

For many pilots and maintenance teams, Aeroshell W100 and Aeroshell W100 Plus stand out as two of the most trusted choices on the market—yet deciding between them isn’t always straightforward.

Both oils are mainstays in general aviation, each engineered with a distinct purpose and additive package. If you’re comparing Aeroshell W100 vs. W100 Plus, this guide breaks down what sets them apart and how to confidently choose the right option.

What Is Aeroshell W100?

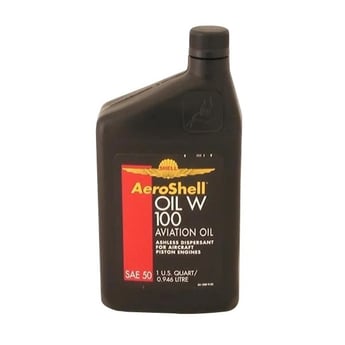

Aeroshell W100 is a premium, single-grade, ashless dispersant aviation piston engine oil, widely used across general aviation.

It falls within the same family as Aeroshell’s 65, 80, and 120 series—straight mineral oils formulated from carefully selected high viscosity index base stocks. These oils contain no dispersant additives aside from small amounts of pour-point depressant (which helps the oil flow better in cold temperatures) and a minimal antioxidant.

Aeroshell W100 is engineered to meet SAE J-1966 standards (SAE 50 grade) and holds both U.S. and U.K. military qualifications. As a result, it’s approved for all civil aviation piston engines requiring a non-dispersant oil.

It’s also a long-standing favorite for engine break-in because its formulation allows piston rings to seat properly, helping maximize compression and long-term performance.

Aeroshell W100 Key Benefits

- Ideal for Break-in Periods: Its straight mineral base oil formulation allows for efficient ring seating in new or recently overhauled engines.

- High Viscosity Index for Improved Protection: The specially blended base oils maintain stable viscosity even under high stress, helping protect components during demanding operations.

- Additive-free Formulation: W100 contains no dispersant additives (beyond minimal pour-point depressant), making it suitable for engines requiring undoped mineral oils.

- Proven Performance: With approvals from major engine manufacturers and compliance with SAE and military specifications, W100 has built decades of trust throughout general aviation.

- Confidence Between Overhauls: The high-quality mineral base oils help safeguard internal components, contributing to consistent performance until the next scheduled major maintenance.

What is Aeroshell W100 Plus?

Aeroshell W100 Plus takes the familiar W100 formula and adds modern additive technology to address real-world issues such as corrosion, wear, and deposit formation—especially common in underutilized aircraft engines.

It’s still a single-grade SAE 50 oil, but it incorporates the same ashless dispersant technology used in Aeroshell’s multigrade oils, plus several specialized additives.

This enhanced formula includes:

- An anti-wear additive (the Lycoming-approved LW 16702)

- A corrosion inhibitor

- A metal passivator to protect copper components

- A dispersant additive to keep the engine cleaner

In other words, Aeroshell W100 Plus provides all the viscosity stability and base stock quality of W100, but with the extra protection today’s aircraft engines often need—especially Lycoming engines that require additive LW 16702.

Aeroshell W100 Plus Key Benefits

- Built-in Lycoming LW 16702 Additive: No need for supplemental additives. This is particularly important for Lycoming engines covered under service bulletins requiring additional wear protection.

- Superior Rust and Corrosion Protection: Ideal for aircraft that sit between flights, operate in humid environments, or fly only seasonally. Its corrosion inhibitors reduce one of the most common causes of premature engine wear.

- Enhanced Anti-wear Performance: The load-carrying additive reacts only when metal-on-metal contact occurs—such as during start-up—coating surfaces with a protective layer without impacting oil flow.

- Cleaner Engine Operation: The non-ash-forming dispersant additive helps minimize spark plug fouling and reduces harmful combustion chamber deposits.

- Protects Copper Components: The metal passivator prevents copper in camshafts and other components from accelerating oil degradation.

- Seamless Compatibility: W100 Plus can be mixed with other approved aviation piston oils (though doing so may reduce its performance advantages).

Aeroshell W100 vs. W100 Plus: Comparison Chart

Aeroshell W100 is the classic workhorse, while Aeroshell W100 Plus is the enhanced, modernized version designed for today’s operational challenges.

Here's a quick side-by-side look at how the two oils differ:

|

Category

|

Aeroshell W100

|

Aeroshell W100 Plus

|

|

Oil Type

|

Straight mineral, no dispersant

|

Single-grade ashless dispersant with enhanced additives

|

|

SAE Grade

|

SAE 50

|

SAE 50

|

|

Lycoming LW16702 Additive

|

Not included

|

Included—meets Lycoming requirements

|

|

Corrosion Protection

|

Basic

|

Advanced corrosion inhibitors for better protection during periods of non-use

|

|

Wear Protection

|

Standard mineral oil protection

|

Advanced anti-wear additive for start-up and high-load components

|

|

Deposit Control

|

Minimal additive content

|

Ashless dispersant additive for cleaner operation

|

|

Compatibility

|

Works with most piston engines

|

Works with most piston engines; not for helicopter common sump systems or break-in

|

|

Ideal Use

|

Engine break-in, engines requiring non-additive oil

|

Operational engines requiring anti-wear and corrosion protection

|

|

Best For

|

Routine flying, flight schools

|

Aircraft flown periodically, humid climates, engines prone to corrosion

|

How to Decide Whether to Use Aeroshell W100 vs. W100 Plus

Choosing between Aeroshell W100 vs. W100 Plus plus largely depends on your aircraft’s usage patterns, engine type, environment, and maintenance philosophy.

Here’s how experienced aviation technicians and operators typically approach the decision:

#1. Consider How Often the Aircraft Flies

Frequent Flyers (High Utilization)

W100 performs well for training aircraft, rental fleets, and operators who fly several times per week. These engines are less prone to internal corrosion because moisture doesn’t sit inside the engine for long.

Infrequent Flyers (Seasonal Operation)

W100 Plus is strongly recommended. If your aircraft sometimes sits for a week or longer—which is very common in general aviation—the corrosion inhibitors provide meaningful protection during downtime.

#2. Evaluate Environmental Conditions

- Dry Climates: Either oil works well.

- Humid, Coastal, or Variable Environments: W100 Plus offers significantly better rust protection.

- Cold Weather Operations: You may consider moving to a multigrade, but between these two, W100 Plus still delivers better start-up protection.

#3. Assess Engine Type and Manufacturer Recommendations

Lycoming specifies the LW 16702 anti-wear additive for several models. If your engine falls under these service bulletins:

- Aeroshell W100 Plus already contains LW 16702, eliminating the need for any supplemental additive.

- W100 would require you to add LW 16702 separately—adding cost and complexity.

#4. Think About Engine Longevity Goals

Operators focused on maximizing time between overhauls (TBO) increasingly choose W100 Plus because:

- Its anti-wear additive protects internal components when lubrication is most marginal, especially at start-up.

- Its metal passivator and corrosion inhibitors protect the oil from chemical degradation and shield internal components from rust.

#5. Break-in vs. Ongoing Operation

Use Aeroshell W100 for break-in. After break-in, you can transition to W100 Plus for ongoing protection and cleaner operation.

Summary: Aeroshell W100 vs. W100 Plus

If you want the simplest general guidance:

Choose Aeroshell W100 if:

- You’re breaking in an engine, or

- Flying frequently in mild conditions.

Choose Aeroshell W100 Plus if:

- You want enhanced protection,

- Fly irregularly, or

- Operate a Lycoming engine requiring the LW 16702 additive.

We’ll Help You Decide Between Aeroshell W100 vs. W100 Plus

Selecting the right oil isn’t always easy—especially when you’re balancing engine requirements, environmental factors, flying habits, and long-term maintenance goals. That’s where the aviation experts at Keller-Heartt come in.

We’ve supported aircraft owners, FBOs, flight schools, and maintenance shops for decades, and we understand exactly how critical the right oil is to safe, reliable operation.

Whether you’re comparing Aeroshell W100 vs. W100 Plus, transitioning out of break-in, or looking for the best long-term maintenance strategy, we’re here to help you choose confidently.

You can also place your order online anytime. We offer:

- Fast, free shipping on every order

- Bulk discounts on Aeroshell oils

- Buy 3+ → Get 3% off

- Buy 7+ → Get 5% off

Your aircraft deserves the highest-quality lubrication—and Keller-Heartt is here to make that easy, cost-effective, and stress-free.